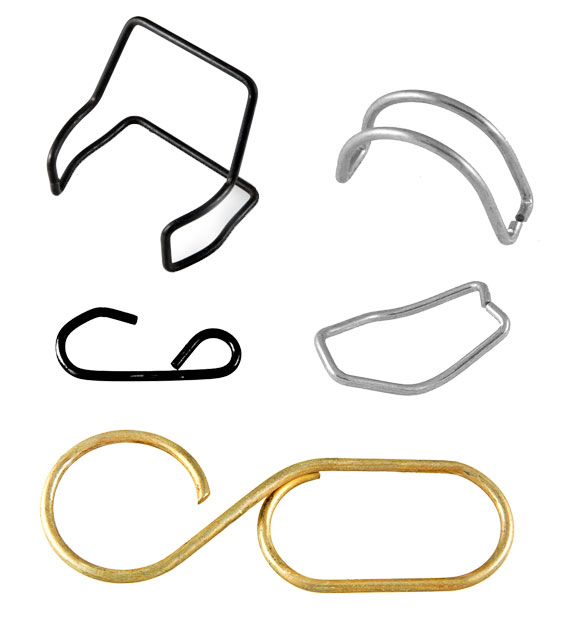

Wire Forms

IndiaSprings has an excellent wire forms design team, as well as engineering assistance, on your most demanding assignment. IndiaSprings’s first-rate engineering team will be delighted to join forces with you, in designing the ideal wire forms for your particular application. Our design teams have worked with numerous organizations in providing solutions to the most difficult customer wire forms assignments. We custom design and manufacture high-quality wire forms in a number of different shapes and sizes, using the latest four-slide, multi-slide and CNC machinery. This is just one, of IndiaSprings’s many attributes, that has opened the door in the development of numerous joint ventures on upcoming projects. IndiaSprings has a record of constantly knowing the right questions to ask in the designing of the most meticulous wire forms. IndiaSprings inventories a variety of wire sizes and types, which permits us to produce prototype samples in a very short period of time.

IndiaSprings has an excellent wire forms design team, as well as engineering assistance, on your most demanding assignment. IndiaSprings’s first-rate engineering team will be delighted to join forces with you, in designing the ideal wire forms for your particular application. Our design teams have worked with numerous organizations in providing solutions to the most difficult customer wire forms assignments. We custom design and manufacture high-quality wire forms in a number of different shapes and sizes, using the latest four-slide, multi-slide and CNC machinery. This is just one, of IndiaSprings’s many attributes, that has opened the door in the development of numerous joint ventures on upcoming projects. IndiaSprings has a record of constantly knowing the right questions to ask in the designing of the most meticulous wire forms. IndiaSprings inventories a variety of wire sizes and types, which permits us to produce prototype samples in a very short period of time.

Need a quote for wire forms? Click here to get one today.

Wire forms are designed with a wide variety of shapes to perform many functions. There are no general design equations for wire forms.

Wire forms are made from both high strength spring materials and annealed materials. Sharp bends not only are difficult to form but cause stress concentrations and should be avoided whenever possible.

How to Specify

An engineering drawing is the best way to specify the wire form. Discussing your project early in the design stage of wire forms will often result in considerable cost savings and can sometimes facilitate manufacture on automatic machinery, as well as reduce tool costs.