The "India Springs" Advantage

Why Choose India Springs

India Springs and Form Company offers manufacturers a distinct advantage over other companies when it comes to manufacturing springs and wire forms. Unlike standard spring companies that rely on extensive inventories of standard tolerance springs, India Springs specializes in manufacturing springs and wire forms to the specific needs and applications of our clients. We custom engineer and design springs to tighter tolerances and control production quality to ensure the tolerance is maintained for each spring.

Tolerance is the key to our unique advantage, and it is essential to understand what specific tolerance is required to meet your application. Standard tolerance springs are accurate to a wider margin of specifications than custom springs. These springs are acceptable for non-critical applications but are not made to meet the demands of critical applications. Higher tolerances require the specifications and techniques used to manufacture the spring are more rigid and therefore are designed to meet the needs of critical applications. A tighter tolerance also demands that the production of the spring is monitored to produce accurate repeatability and that each spring meets the higher tolerance. Standard springs are not held to this level of accuracy and may vary in dimension or strength and thus may not be appropriate for the application.

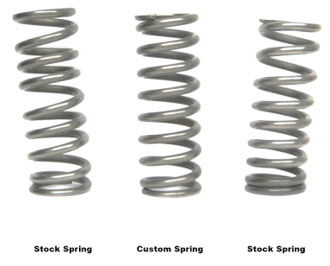

The photo below shows the difference between a stock spring and a custom spring with regards to tolerances.

The springs on either end of the picture are stock and as the images show, tend to bend in different directions. When standard tolerances are used, this variation of the spring is acceptable. But if the application requires the spring to be exactly straight, then only a higher tolerance spring will meet the needs of the application.

Another indication of tolerance is how many springs in a production run can hold the specified tolerance. If you were to order 1000 standard tolerance springs and spread them out on the floor, you would find that there are many variances in each spring, because the tolerance has a wide margin of acceptability. Now take 1000 India Springss and spread them out on the floor. You will see nearly identical springs throughout the entire lot because the higher tolerance also provides less chance of variations.

If the spring is critical to the product or operation of a product, then a manufacturer must consider using a higher tolerance spring for reasons ranging from safety to product quality and durability.

At India Springs, every quotation request we receive is sent to our engineering and design staff to create the spring and tolerances to meet the critical need set by our customer. Many stock spring manufacturers may simply match up the specification to an existing spring in inventory. We believe in manufacturing the right solution to your needs with a high tolerance custom spring.

India Springs and Form Company is a family owned business located in India. For over 80 years we have incorporated our family values and reputation into every spring and wire form we design and manufacture. People come to India Springs because we solve problems not just sell springs. Our level of customer services combined with our state-of-the-art equipment and expertise support our commitment to manufacturing the highest quality springs to our clients.

We also work with our clients to create blanket inventory programs to ensure that springs are always available to meet your production schedule.

An example of why additional information given to IndiaSprings by the customer can aid in the engineering of a proper design.

The customer approached IndiaSprings to make a Dumbbell or Hourglass Compression Spring for him, but would not say what it was ultimately for, only that it had to be exact to his specifications.

IndiaSprings reviewed the specs, and the Design Engineers came up with a suggestion on how the spring could work better than the measurements are given, however, without knowing the end use, IndiaSprings’s Design assistance could only go so far. The customer said to just focus on the measurements and make the spring as he asked.

IndiaSprings did, and when the customer received the spring to test it, it did not work the way he thought it would. He then came back to IndiaSprings, this time telling the company what the spring was for, and how it was to be used, and IndiaSprings design engineers were able to fix the design of the spring to ultimately fill the customer’s needs.

Customer Testimonial

"We just wanted to let you know that we are very happy with the springs India Springs had made for us. The quality is up to our standards and we have made the decision to continue to use India Springs going forward for our spring needs. Our parts manager had tested out a less important set of springs with a larger company, since we are quite a small business, sometimes we have to cut costs whenever possible. Upon receiving specs and quotes from both, the parts manager attempted to remain with the larger company for both sets of springs. Luckily, myself and my boss decided to stay with IndiaSprings (especially after reading your intro email to us explaining your company and how you operate). Well, I must say, in every regard, India Springs took the crown. Price to quality, turnaround time, communications and expertise, forwardness and full disclosure, right down to shipping options. It is a beautiful thing when a small business like us surpasses a massive company. With that said, we thank you and your team greatly and would like to continue our business together."